HKLT Series turbine flow meter (better described as an axial turbine) translates the mechanical action of the turbine rotating in the liquid flow around an axis into a user-readable rate of flow (gpm, lpm, etc.). The turbine tends to have all the flow traveling around it.

The turbine wheel is set in the path of a fluid stream. The flowing fluid impinges on the turbine blades, imparting a force to the blade surface and setting the rotor in motion. When a steady rotation speed has been reached, the speed is proportional to fluid velocity.

Turbine flow meters are used for the measurement of natural gas and liquid flow. Turbine meters are less accurate than displacement and jet meters at low flow rates, but the measuring element does not occupy or severely restrict the entire path of flow. The flow direction is generally straight through the meter, allowing for higher flow rates and less pressure loss than displacement-type meters. They are the meter of choice for large commercial users, fire protection, and as master meters for the water distribution system. Strainers are generally required to be installed in front of the meter to protect the measuring element from gravel or other debris that could enter the water distribution system. Turbine meters are generally available for 4 to 30 cm (1 1⁄2–12 in) or higher pipe sizes. Turbine meter bodies are commonly made of bronze, cast Iron, or ductile iron. Internal turbine elements can be plastic or non-corrosive metal alloys. They are accurate in normal working conditions but are greatly affected by the flow profile and fluid conditions.

HKLT Series

Turbine Flowmeter

|

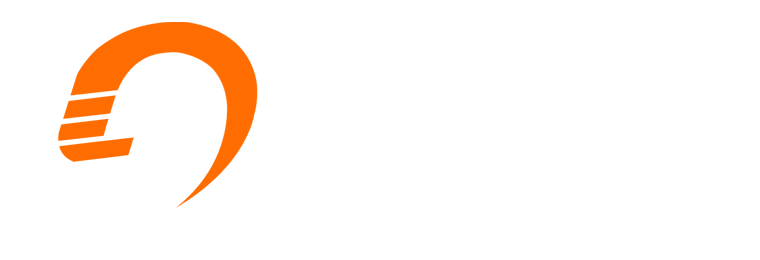

HKLT/C

|

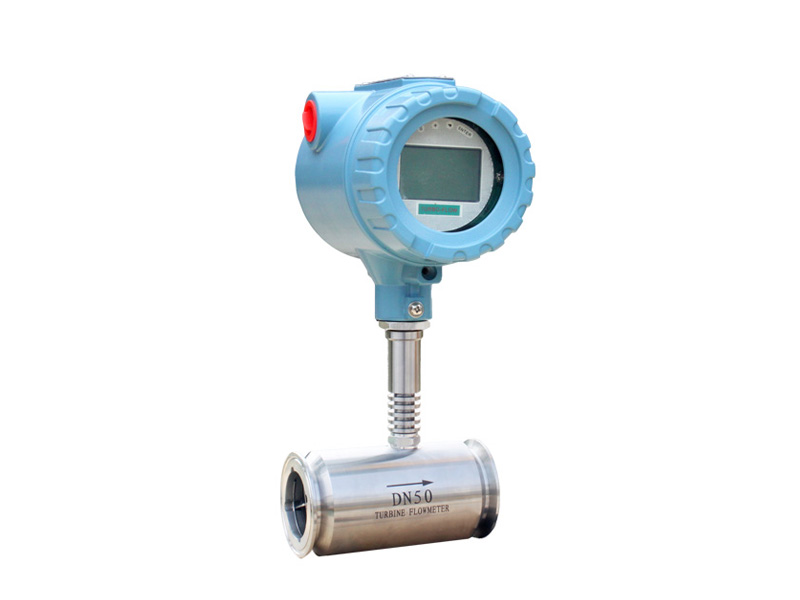

HKLT/T

|

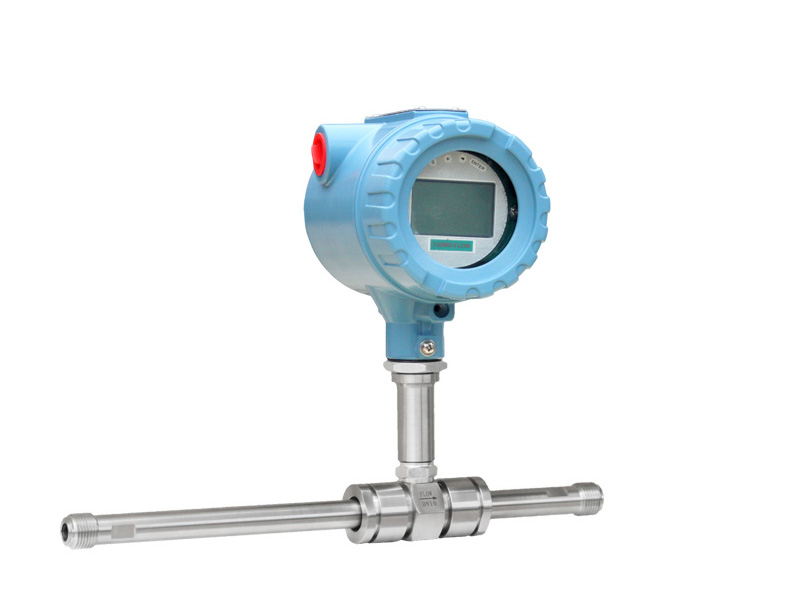

HKLT/F

|

Clamp Type

|

Thread Type

|

Flange Type

|

Medium

|

Liquid

|

Accuracy

|

±1.0%, ±0.5%, ±0.2%(Customized)

|

Measure Ratio

|

1:10, 1:15, 1:20

|

Sensor Material

|

SS304, SS316L etc

|

Work Condition

|

Media Temperature: - 20°C ~120°C

Ambient Temperature: - 20°C ~ 60°C

Relative Humidity: 5% ~90%

Atmosphere: 86KPa~106KPa

|

Signal Output

|

Pulse. 4-20mA

|

Communication

|

RS485, HART

|

Power Supply

|

Outside Power Supply: 24V DC + 15%, Ripple≤±5%, apply to 4-20mA output, pulse, RS485Communication;

Internal Power Supply: 3.6V 10AH Lithium Battery, regular work when voltage in the range of 2V~3V

|

Cable Entry

|

Basic model: Houseman Joint or three core cable.

Explosion proof model: Internal thread M20*1.5

|

Explosive-proof

|

Flameproof Exd II BT3~6, Instrinsical Safe Exia II CT3~6

|

Protection Class

|

IP 65 or higher grade for option

|

-

High accuracy; normal type can reach +1.0% R, +0.5% R. High accuracy type can reach to +0.25%R;

-

Excellent repellent repeatability, repeatability in a short time can reach to 0.05%~0.2%. Due to the excellent repeatability, customer can use it for trade purpose;

-

Output pulse frequency signal, suitable for total flow measuring and connecting computer, no zero drift and strong ability in anti-noise;

-

High frequency signal (10HZ~1.5HZ), strong signal resolution;

-

Wide turn down ratio, Max 1:20;

-

Compact and light structure, convenience in installation and maintenance;

-

Suitable to measure in high pressure. No need to open aperture on the meter, so it is seasy to make high pressure meter.